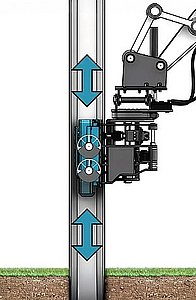

Competition (conventional technology)

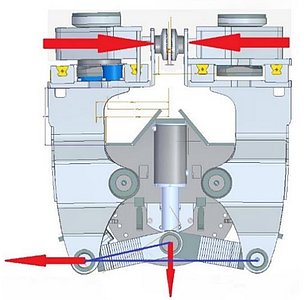

With conventional systems, the vibration takes place in a range of 80-90 cm outside the pile. As a result, valuable energy is lost and the efficiency of the pile driving process is significantly impaired.

Consequences of this inefficient vibration transmission:

- Energy loss: Up to 30 % of the energy is lost as the vibration is not fully transferred to the pile.

- Snaking line effect: Uncontrolled vibrations lead to “snaking lines”, which cause increased ground vibrations and impair the precision of the ramming process.

- Material fatigue: Cracks in the arms are caused by extreme load peaks and uncontrolled vibrations.

- Component wear: Excessive stress on the rubber dampers due to overloading leads to premature damage.

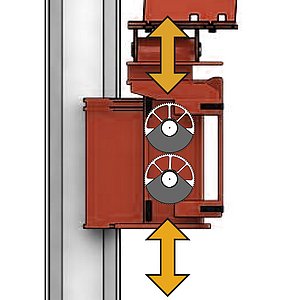

EMB ⦁ RAM CENTRIC ⦁ HIT - Technology

The CENTRIC ⦁ HIT - TECHNOLOGY impresses with its particularly low dynamic weight - up to 50 % less mass compared to conventional systems.

As only the vibration housing is set in vibration, this results in decisive advantages:

- Higher performance: 50 % less mass enables 50 % higher performance,

- Efficient energy transfer: No unnecessary masses need to be accelerated.

This results in maximum energy efficiency, optimised power transmission and significantly reduced wear, which considerably improves the service life and cost-effectiveness of the system.

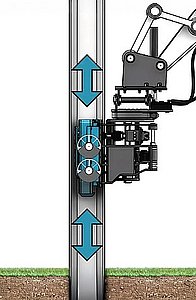

Competition (conventional technology)

Conventional systems have an excessively high dynamic weight, as several heavy components have to be set in vibration:

- Vibration housing

- Clamping arms with respective holders

- Hydraulic cylinders

- Hydraulic motors

The resulting disadvantages:

- Loss of power: 50 % less power, as unnecessary masses are also accelerated.

- Increased energy consumption: Reduced efficiency due to unnecessary effort.

- Higher component load: Accelerated wear and increased maintenance costs.

- Inefficient vibration transmission: Impeded propulsion of the pile-driving material.

These factors lead to significantly lower pile driving performance, higher operating costs and inefficient utilisation of the energy generated.

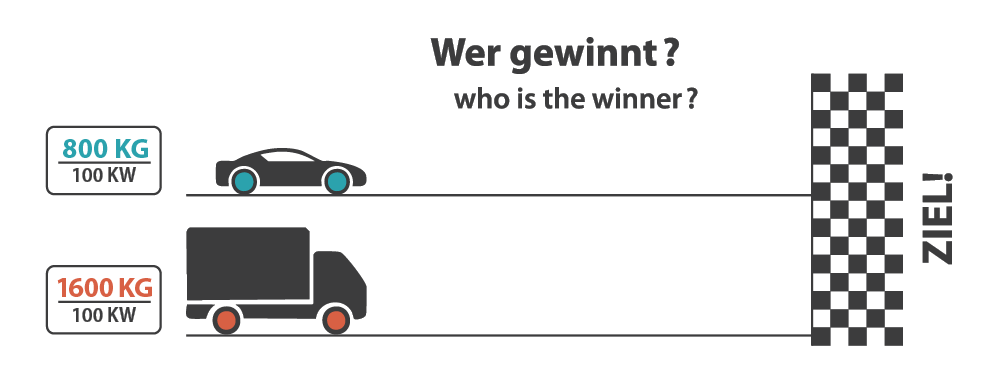

Practical example: Dynamic weight

Explanation:

If two cars have the same performance, the lighter vehicle always wins, as less mass has to be moved and the energy is converted more efficiently into acceleration.

This principle also applies to ramming technology: a lower dynamic weight leads to higher performance, better energy efficiency and reduced wear, as no unnecessary masses need to be accelerated.

EMB ⦁ RAM CENTRIC ⦁ HIT - Technology

The minimised shaking of the pile-driving material significantly reduces both noise and ground vibrations, which considerably improves the efficiency and environmental compatibility of the pile-driving process.

The decisive advantages:

- Less noise emissions: Optimised working conditions and easier compliance with environmental regulations.

- Reduced ground vibrations: Minimised risk of damage to surrounding structures.

- Maximum energy efficiency: Power is channelled into driving the pile instead of being lost through uncontrolled vibrations.

The result:

A powerful, precise and environmentally friendly piling process with optimised energy transfer.

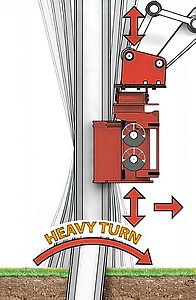

Competition: (conventional technology)

Disadvantages due to heavy shaking of the pile

A strong vibration of the pile driving material has considerable disadvantages that impair the efficiency and cost-effectiveness of the pile driving process:

- High noise level: stress on the working environment and need for additional noise protection measures.

- Strong ground vibrations: Hazard to surrounding structures and potential damage.

- Increased energy loss: A significant proportion of the vibration energy is released uncontrollably instead of being channelled into driving the pile.

- Increased maintenance costs: Faster wear of central components such as clamping jaws, hydraulic cylinders and damping elements due to additional loads.

The result:

Lower efficiency, higher operating costs and an overall less economical piling process.

EMB ⦁ RAM CENTRIC ⦁ HIT - Technology

Advantages of Centric Hit technology:

- No shaking of the pile, which prevents energy loss and unwanted vibrations.

- Low ground vibration, which protects surrounding structures and minimises environmental impact.

- Low noise, which improves working conditions and reduces noise emissions.

- Low maintenance costs due to reduced wear on clamping jaws, hydraulic cylinders and damping elements.

Competition: (conventional technology)

Disadvantages of the competition (conventional technology)

- Strong shaking of the pile-driving material

→ Energy losses and uncontrolled movements - ‘Snaking lines’

→ Uneven propulsion and increased ground vibrations - Large ground vibrations

→ Stress and possible damage to surrounding structures - High noise level

→ Impairment of the working environment and increased noise protection requirements - High friction in the locks of the pile-driving material

→ Increased material wear and possible fitting problems - Cracks in the rubber dampers

→ Excessive load due to uncontrolled vibrations - Heavy wear on the clamping jaws

→ Shortened service life due to uneven application of force - Bending and damage to the pile-driving material

→ Imprecise application of force leads to material damage

EMB ⦁ RAM CENTRIC ⦁ HIT - Technology

CENTRIC ⦁ HIT - Advantages of the special cylinder arrangement

The special arrangement of the cylinder with corresponding deflection creates an extremely high clamping force on the clamping jaws, which can be individually adjusted - up to 130 tonnes.

This results in the following advantages:

- Very good transmission of the vibration to the pile-driving material

→ Maximum efficiency and precise propulsion - No or little wear on the clamping jaws

→ Longer service life and lower replacement costs - No damage to the pile

→ Gentle but powerful clamping - Low service costs

→ Less maintenance and reduced operating costs

Competition: (conventional technology)

Competition - Standard cylinder linkage

Only 50-60 tonnes of clamping force are possible with the conventional cylinder linkage.

This leads to several disadvantages:

- Lower transmission of vibration to the pile

→ Less power and higher energy loss - High wear on the clamping jaws

→ Increased wear and shortened service life - Welding between clamping jaws and pile-driving material

→ Material build-up and impairment of function - Damage to the pile-driving material

→ Uneven clamping force can cause deformation - High service costs

→ Increased maintenance costs and more frequent repairs