30 % lower maintenance and repair costs

Extremely strong gripping

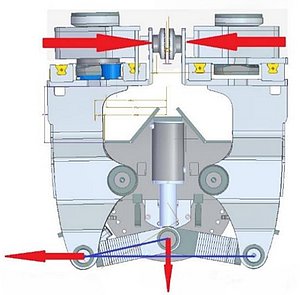

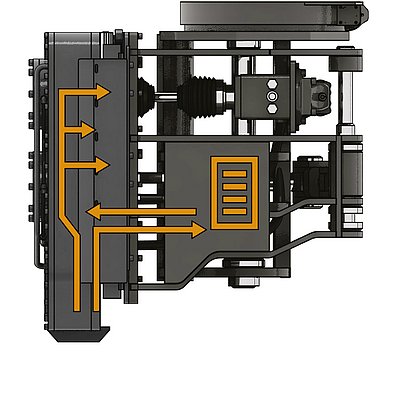

CENTRIC ⦁ HIT - Advantages of the special cylinder arrangement

The special arrangement of the cylinder with corresponding deflection creates an extremely high clamping force on the clamping jaws, which can be individually adjusted - up to 130 tonnes.

This results in the following advantages:

- Very good transmission of the vibration to the pile-driving material

→ Maximum efficiency and precise propulsion - No or little wear on the clamping jaws

→ Longer service life and lower replacement costs - No damage to the pile

→ Gentle but powerful clamping - Low service costs

→ Less maintenance and reduced operating costs

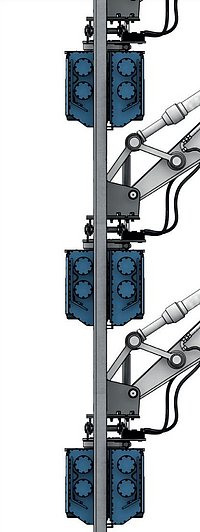

EMB ⦁ RAM CENTRIC ⦁ HIT - Technology

Advantages of CENTRIC ⦁ HIT Technology

- No shaking of the pile, which prevents energy losses and unwanted vibrations.

- Low ground vibration, which protects surrounding structures and minimises environmental impact.

- Low noise, which improves working conditions and reduces noise emissions.

- Low maintenance costs due to reduced wear on clamping jaws, hydraulic cylinders and damping elements.

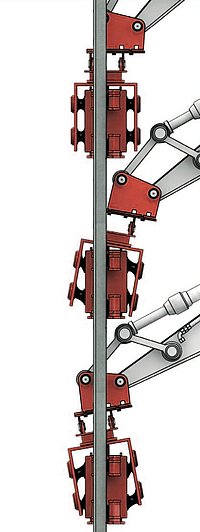

Competition (conventional technology)

Disadvantages of the competition (conventional technology)

- Strong shaking of the pile-driving material

→ Energy losses and uncontrolled movements - ‘Snaking lines’

→ Uneven propulsion and increased ground vibrations - Large ground vibrations

→ Stress and possible damage to surrounding structures - High noise level

→ Impairment of the working environment and increased noise protection requirements - High friction in the locks of the pile-driving material

→ Increased material wear and possible fitting problems - Cracks in the rubber dampers

→ Excessive load due to uncontrolled vibrations - Heavy wear on the clamping jaws

→ Shortened service life due to uneven application of force - Bending and damage to the pile-driving material

→ Imprecise application of force leads to material damage

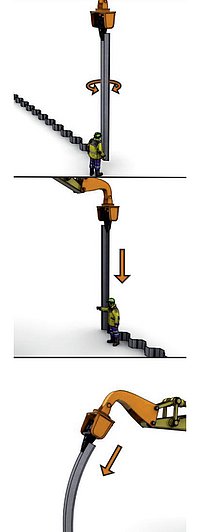

Active control

When the vibration is activated on the joystick, the EMB ⦁ RAM Control System actively intervenes and, depending on the vibration mode selected, sets either the bucket tipping cylinder or both the bucket tipping cylinder and the tilt cylinder to the floating position. This makes it much easier for the pile to penetrate the ground and automatically prevents the formation of snaking lines to minimise ground vibrations.

The system is also equipped with a safety cut-out, which ensures that the floating function or vibration is only activated when the appropriate counter-pressure is applied. This means that the pile must be in clear contact with the ground and sufficiently pressed in before the process starts.

EMB ⦁ RAM LUBRICATION SYSTEM

EMB ⦁ RAM LUBRICATION SYSTEM

This advanced lubrication technology not only significantly extends the service life of the components, but also improves the efficiency and reliability of the entire mounted vibrator. The system ensures smooth operation, minimises the risk of unplanned downtime and makes a significant contribution to the operational safety and performance of the machine.