CENTRIC ⦁ HIT Technology

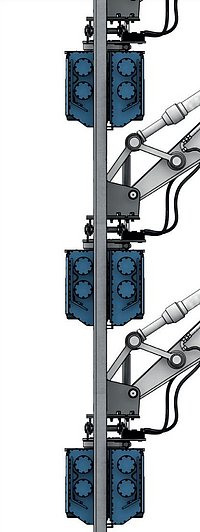

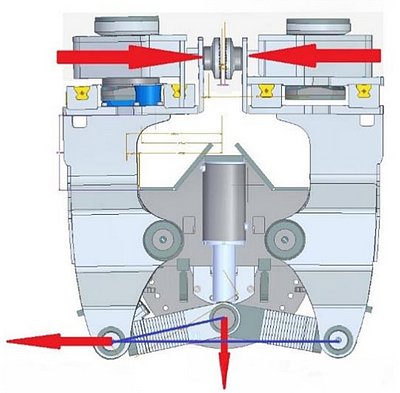

CENTRIC ⦁ HIT - TECHNOLOGY grips the pile centrally so that the vibration unit is positioned exactly in the centre of the pile and transmits the vibration optimally. This innovative technology ensures an even application of force, minimises material stresses and maximises the efficiency of energy transfer, making the pile-driving process more precise, powerful and gentle on the pile.

Dynamic weight

The CENTRIC ⦁ HIT - TECHNOLOGY has a 50 % lower dynamic weight than all competitors. This means that no unnecessary masses need to be accelerated. This increases energy efficiency, reduces wear and optimises the performance of the ramming process.

Avoidance of snaking lines

The CENTRIC ⦁ HIT - TECHNOLOGY ensures that snaking lines are avoided by gripping the pile in the centre. The straight-line insertion of the pile into the ground ensures precise positioning, minimises ground vibration and thus increases the efficiency and stability of the pile-driving process.

No ‘falling wall’ problem

The CENTRIC ⦁ HIT - TECHNOLOGY prevents the wall (piling/sheet pile) from ‘falling’. The centred gripping and straight-line power transmission ensure stable guidance of the pile, guaranteeing a controlled and precise driving process. This improves pile driving quality, increases safety on the construction site and enables faster, more efficient working methods.

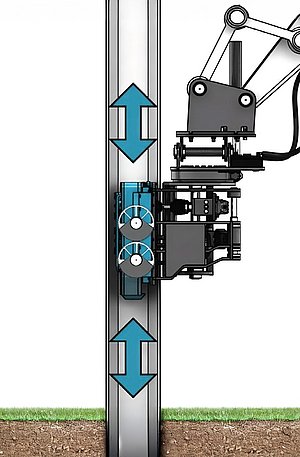

Double linear guide

The precisely fitting double linear guide stabilises the two vibra housings so that the vibration is generated exclusively by a precise up and down movement. As a result, no undesirable axial forces are exerted on the pile, which ensures precise force transmission. This leads to a significant increase in propulsion, optimises energy transfer and maximises the efficiency of the piling process.

Extremely strong gripping

The CENTRIC ⦁ HIT - TECHNOLOGY enables extremely powerful and precise gripping of the pile thanks to an individually adjustable pressing force. If required, a pressing force of up to 130 tonnes can be generated, ensuring optimum vibration transmission and maximising the efficiency of the piling process. At the same time, this high pressing force minimises wear as it prevents the jaws from burning.